Solex turns your demand, sales commitments, production constraints, and stockpiles into one real‑time plan your sites can actually run. The AI decision engine does the heavy modeling in the background and gives your planners and site leads clear actions, so margin is captured instead of leaking out in the gaps.

Solei partners with you for the change management, so the system gets used and the gains show up on the P&L.

With 60+ Years of combined Aggregate Expertise, our leadership team has led successful digital and AI transformations inside Fortune 100 companies.

Your Margin Is Leaking Because The Plan Is Always Behind Reality

Most aggregates producers are leaving seven figures on the table every year because sales, planning and production never share one live, profit-driven plan. The result is predictable: missed high-value demand, the wrong mix, excess inventory, and firefighting costs that hit EBITDA and cash flow.

Lost high-margin sales

Premium orders you could have filled but did not, because production was scheduled on stale forecasts instead of live demand.

Cash trapped in the wrong inventory

Millions locked in slow-moving material while capital costs rise, and plants are forced into constant re-planning to meet the mix that is actually needed.

5–10% higher handling and operating cost.

Stockpile imbalances and last-minute plan changes drive additional re-handling, fuel consumption and equipment wear across the sites.

Overtime and emergency spend

Schedule swings that force weekend shifts, rushed maintenance and reactive fixes that could have been seen weeks ahead.

Quiet margins bleed every month

Conservative operating modes protect tonnage but destroy mix value and profit per ton.

The cost is compounding every day you wait.

Every margin point is worth multiples

Industry margins and valuations are at record highs, so every point of performance you leave on the table is worth more than ever.

The experience buffer is shrinking

Experienced operators are retiring, taking decades of unwritten know-how with them, while new managers are stretched across more sites.

First-mover advantage.

Modern AI planning tools are finally ready for this complexity, which means competitors who move now will lock in structural cost and mix advantages while others chase from behind.

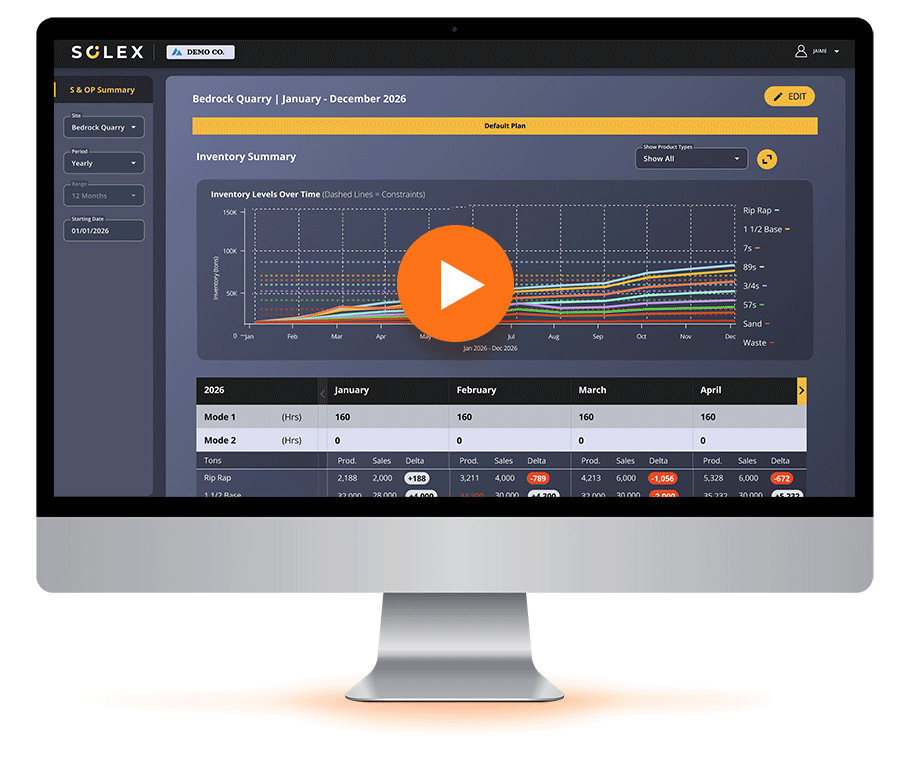

Solex Is the Operator-friendly, Real-time S&OP Platform

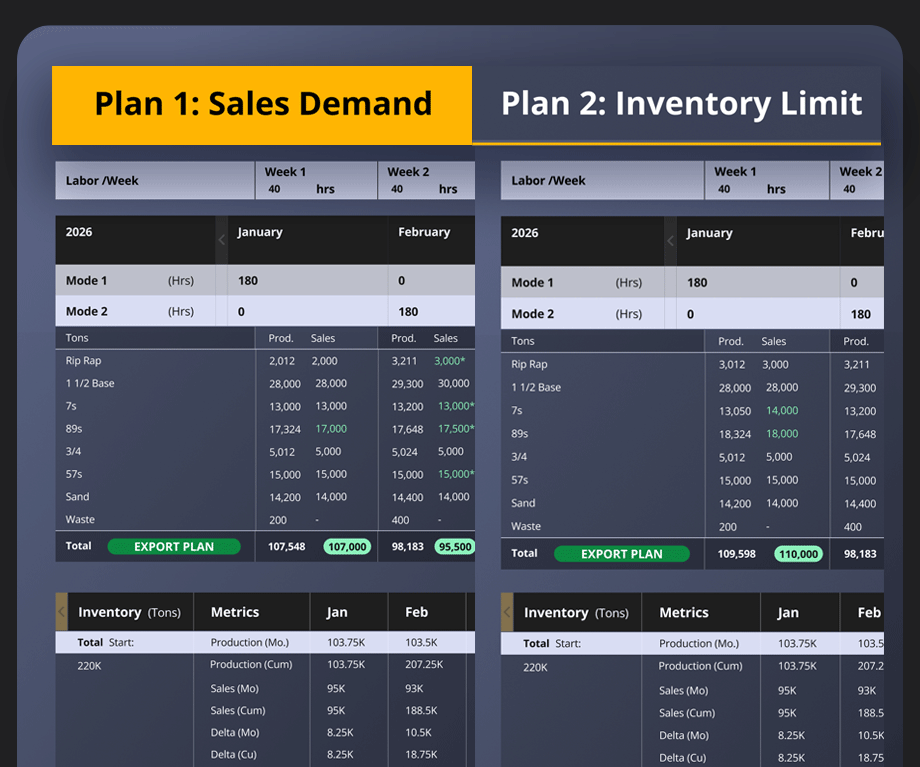

Solex is the AI decision engine built specifically for aggregates. It connects market demand, production planning, inventory, and margin in one unified system, turning scattered operational data into a profit-driven plan your teams can run: what to produce, where, when, and why it’s the highest‑value choice.

Complex Math, Simple Decisions

It’s built around the daily rhythm of aggregates operations, so it’s usable under pressure. An AI engine under the hood handles the complex modeling; teams see a clear, straightforward screen with the actions they need to take.

What Solex does for you:

One source of truth for the plan

Demand, capacity, and stockpiles in one place, so sales and operations stop running different versions of reality.

Profit-first recommendations.

Clear guidance on product mix, modes, and shifts, with the margin impact of each decision.

Inventory That Doesn’t Burn Cash

Better stockpile balance and fewer “wrong pile” situations that force re-handling and tie up working capital.

Real-time signals, not lagging reports.

The system surfaces what’s changing now so you can adjust margin before it is gone.

Built to be used by teams with ease.

Simple, straightforward interface, while AI does the heavy calculations under the hood.

The Math Is Simple: ~6× ROI

In a typical aggregates network, Solex is designed to target a conservative ~5% productivity / cost improvement per site, and network rollouts compound from there. That translates into roughly $6 back for every $1 spent, year over year.

1

Typical Site Economics:

~700k tons/year and ~$6M in annual operating cost (assumed baseline).

2

5% Improvement =

~$300k/Year Per Site.

That’s the value of better mix decisions, fewer rehandles, and fewer wasted run hours.

3

Network Impact Compounds.

$300k × 20 sites = ~$6M/year in recurring savings (and it scales from there).

Solex becomes the decision engine that keeps production, demand and financial performance aligned, so the financial upside shows up in the P&L.

Clear, Simple Design

Built For Efficiency

Solex is designed so teams can use it in the middle of a busy day. We strip away digital friction by testing directly in the field. Our designer runs on-site usability studies with teams to keep the interface clear, fast and practical in real quarry conditions.

The AI engine does the heavy lifting underneath. On the surface, your teams see a clean screen that shows them what needs to run, where and when, and what that means for inventory, cost and margin.

De-risked Rollout: Prove It On One Site, Then Scale

We start with a focused rollout at a single site over 4 weeks, use it for real planning and daily decisions, and only then expand in waves.

How we roll it out

Single-site launch.

We pick one site, run a face-to-face kickoff, get data flowing in week one and put Solex into the real planning rhythm.

4 week implementation.

Governance and data handoff, configuration, champion training, first live optimization runs and stabilisation, followed by an executive review of results.

Adoption on site.

Teams use Solex for real time decision making, which gives you a real view of fit, impact and feedback from the field.

Wave-based expansion

Once the case is proven, we roll out to additional sites in waves, using a repeatable playbook.

Continuous co-development.

Insights from teams feed back into the product and configuration, so Solex gets sharper as your network grows.

What we need from you

Executive sponsorship with weekly steer-cos

Partner with us on change management

Face-to-face kickoff

Data access and availability in week one

Site level champions for planning and operations

Making this initiative a high priority in your organization

On-site access for our team during the rollout

Feedback loops with your teams

Adoption and Change Leadership: How Solex Sticks

70% of digital transformations fail because organizations struggle to change the behaviors and mindsets that drive decision-making. The real challenge isn’t installing software. The real challenge is reshaping the operating rhythm of the business.

This is where Solex is fundamentally different. We design for behavioral adoption, not just platform deployment.

How We Engineer Adoption:

People-first approach:

We focus on communication, clarity, and the “why” behind each change so crews understand the value from day one.

Team involvement:

Field teams have a voice in workflows and enhancements, increasing ownership and long-term adoption.

Embedded enablement:

Training, on-site support, and integration into daily and weekly planning routines ensure Solex becomes part of how the site actually runs.

Excitement, not resistance:

We make the platform easy to use, easy to trust, and easy to champion across the organization.

The Result: Solex becomes the starting point for every planning conversation. This is behavioral transformation. That is the only thing that makes the ROI stick.

Limited engagement capacity for 2026.

Frequently Asked Questions

By the end of the first month, you will see clear opportunities to recover margin. The full financial picture (around 5% productivity and ~300k dollars per site year over year) becomes clear over the first few planning cycles once the new rhythm settles.

Most S&OP tools fail because they are rigid "top-down" enterprise systems that ignore the reality of the site. Solex is different because it was tested in the field. It adapts to your site’s specific constraints rather than forcing your site to fit a rigid software model.

While Week 1 requires focus for data handoff and orientation, Solex quickly saves time by eliminating the hours spent reconciling spreadsheets, arguing over forecasts, and re-planning shifts. Once Solex is live, using it becomes part of the normal monthly planning rhythm rather than a separate project.

We ingest what you have; you do not need to invent new data streams to start. We need the standard operational inputs you likely already possess: sales forecasts (demand), current inventory levels (stockpiles), and plant production limits (capacity).

In theory, yes — but in practice it requires the mix of wide and deep aggregates operations expertise, digital architecture, AI expertise, UX design, productionizing complex architectures, automating manual processes, and change leadership that most internal teams do not have in one place. Solex gives you a proven decision engine and a team that has already done the heavy lifting, so you are not funding a long, high cost internal experiment.

The engine is complex; the interface is not. The AI handles the heavy calculations in the background. Teams see a clear, straightforward screen showing what to run, where and when, and what it means for inventory, cost and margin. It is built and field-tested so your teams can use it under real site conditions.